Our 5 Tips to Prevent Falls From Height

The first ever No Falls Week starts today. This week, the focus is on raising awareness about the crucial role of safety measures in preventing falls from heights.

Falls from height are still the leading cause of workplace fatalities in the UK. During 2022/23, 40 people tragically lost their lives. Thousands more suffered non-fatal injuries as a result of a fall from height.

You may work in construction or maintenance or be responsible for safety at your premises. In either case, taking proactive steps to reduce risks is key. So, to help you protect yourself, your workers, and others, here are 5 simple steps. Following these will help ensure safety stays a priority.

1. Risk assessments and planning

Before working at height, you must assess risks and plan the work. This step is crucial. It helps to identify hazards and the measures needed to reduce fall risks. Consider environmental factors like weather conditions, uneven or slippery surfaces, and fragile materials.

Risk assessments and careful planning allow you to implement suitable control measures. These are for specific work situations and protect people working at height.

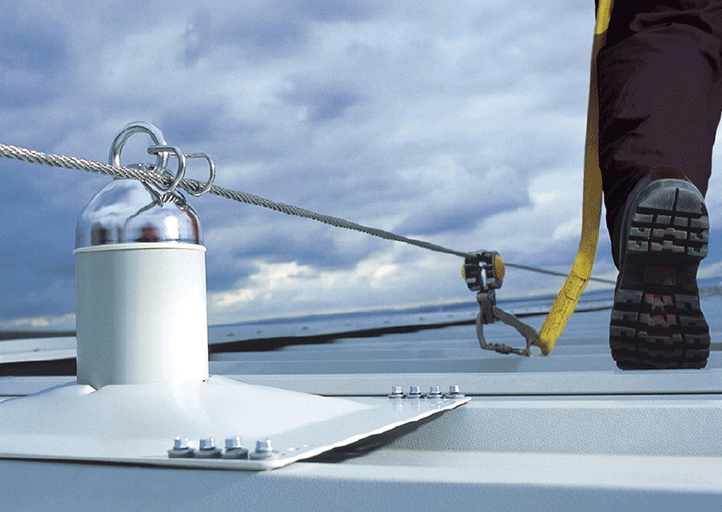

2. Use appropriate fall protection equipment.

If your risk assessment has identified the need for fall protection, use the hierarchy of control to find the best safety solution. Depending on the type of task, different types of fall protection may be necessary. This could include harnesses, guardrails, portable anchors or personal fall protection systems. One of the best ways to prevent falls is with passive or collective equipment, such as guardrails. These don’t need worker involvement and allow safe movement across the entire area.

Before using equipment, you must ensure it fits correctly (for example, PPE), is in good condition, and meets safety standards.

3. Training & Education

Knowledge is vital in preventing falls from heights. Ensure everyone receives full safety training. This includes proper use of equipment. For example, harnesses, lifeline systems, ladders, and mobile elevated work platforms (MEWPs).

Refresher courses and toolbox talks can reinforce these practices. They help keep safety at the forefront of everyone’s minds.

4. Inspect and maintain equipment regularly

Before starting work at heights, check all equipment for wear and tear or damage. In addition to pre-use checks, a competent company must inspect fall protection equipment annually. Any faulty equipment must be replaced or repaired immediately.

Regular inspections and annual tests ensure equipment is working correctly, safe, and compliant.

5. Promote a culture of safety and communication

Create a culture where everyone values safety. This should include everyone from management to maintenance workers and engineers. Then, encourage open discussions about safety concerns. This makes it easier for employees and contractors to report hazards or near misses without worrying about reprisals.

A proactive approach to height safety

The 5 tips we’ve outlined above are a starting point to help you protect people working at height. Of course, there are many more areas to consider when working at height, such as safe access and egress, suitable signage and the safe use of ladders.

By prioritising safety and making it a collective responsibility, you can create an environment where everyone is committed to preventing falls from heights. This is not just for a week, but every week.

The No Falls Foundation organises No Falls Week to educate and empower companies and individuals working at height. Visit the No Falls Week website for more information about the campaign and to access valuable resources covering a range of topics.