As the end of 2024 approaches, it’s natural to start planning for the months ahead. For businesses and contractors working at height, prioritising safety is key to a productive and compliant start to the year. One often overlooked area is testing of fall protection equipment. Before the calendar turns to 2025, why not take a proactive step to ensure your systems are in top condition?

Booking testing, inspection and recertification now not only ensures compliance but also protects the lives of your maintenance team or contractors.

Why regular testing and inspection matters

Falls from height remain one of the highest causes of fatal accidents, particularly in construction, which includes maintenance. HSE 2023-24 statistics released in November show that during this period:

- 138 workers were killed in work-related accidents.

- 50 were as a result of falls from height (28 % of fatal injuries).

- 59% of all fatalities caused by falls from height were in the construction sector.

Whether you’re a building owner, facilities manager, employer or contractor, you must legally ensure the workplace is safe and that equipment is maintained and regularly inspected. For example, the Work at Height Regulations require that fall protection systems are inspected regularly to ensure they’re safe for use.

However, regular inspection, testing, and certification of systems should not be seen as a regulatory requirement or expense. It should be seen as a moral duty.

Here are 7 reasons why recertification of your fall protection systems should be a priority during 2025 and beyond.

1. Legal compliance and risk management

Failure to maintain certifications and meet regulations and standards could result in hefty fines, legal action and reputational damage. It also exposes your workers to unnecessary risks. Regular inspections provide documented evidence and a clear trail of your commitment to worker safety and equipment maintenance.

2. Protecting lives

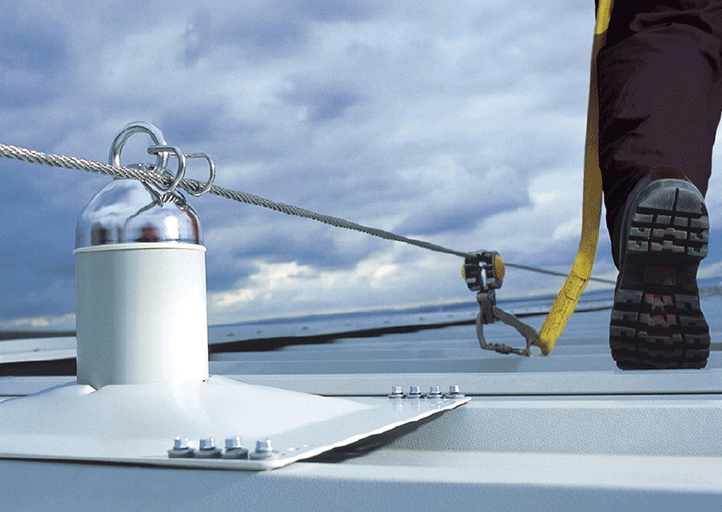

Fall protection equipment is often the last line of defence for workers at height. A harness, lanyard or anchor point might appear fine at first glance, but it could have hidden issues that compromise its integrity. Regular inspections help identify wear and tear, ensuring that your equipment will perform as expected when it’s needed most.

3. Preventing costly accidents

Workplace accidents involving falls from height are the most serious and costly. A single incident can lead to medical expenses, lost productivity and potential lawsuits. Ensuring your equipment is tested and certified reduces the risk of accidents, saving you money and protecting your workforce.

4. Prolonging equipment lifespan with testing

Fall protection represents a significant investment for a company. Routine inspections can identify minor issues before they develop into major problems, extending the lifespan of your equipment. Spotting a frayed strap, loose connection, or unstable edge protection base foot early can save you from prematurely replacing the entire system.

5. Keeping insurance cover intact

Many insurance policies require proof that safety equipment has been maintained and inspected in accordance with industry standards. Neglecting these inspections could void your coverage, exposing your business to financial risks in the event of an incident.

6. Adapting to changing work conditions

Over time, work environments change. For example, have you recently installed solar panels or new equipment on the roof? Systems that were suitable last year might need adjustments or upgrades to align with current conditions. Regular inspections allow experts to identify whether your fall protection system still meets the demands of your workplace or if modifications are necessary.

7. Peace of mind with testing and inspections

Finally, knowing your equipment has been inspected, tested and certified provides invaluable peace of mind. It allows you and your team to focus on the job, confident that every precaution has been taken to ensure safety. It also shows your company values worker safety and proactively protects them.

Start the New Year right

Don’t wait for equipment to fail or for accidents to happen. Proactive scheduling ensures your certification remains current and your equipment stays in good working condition. Remember, fall protection system inspection isn’t just about checking boxes on a form for compliance – it’s about protecting lives.

So, whether you use personal protective equipment, horizontal lifelines, fixed anchor systems or rooftop guardrails, now is the perfect time to schedule your fall protection equipment inspections for the coming year.

Helping you stay safe in 2025

Our comprehensive fall protection services cover all aspects of fall protection. We’ll provide you with detailed reports, including recommendations for maintenance or upgrades, ensuring your equipment is always ready and safe for use.