When was your fall protection system last inspected?

How can you be sure your system is safe and compliant?

How can fall protection equipment become unsafe and non-compliant?

Fall protection systems are installed to specific standards and for particular areas and/or tasks. But over time, the equipment can suffer damage; components can start to corrode. This is why you need to ensure regular inspections of your systems.

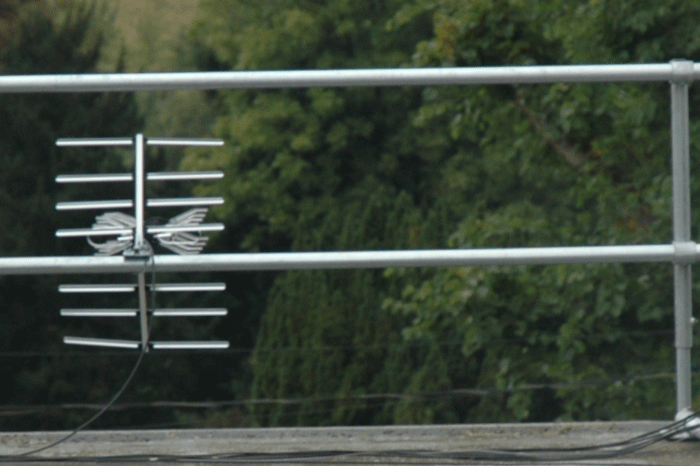

Guardrails and rooftop edge protection

Although these collective systems have no moving parts (apart from collapsible guardrails), they still need inspecting to ensure they remain safe. Galvanised components can show signs of rust or corrosion, or other contractors may tamper with the system.

We’ve also seen aerials and advertising boards attached to a freestanding edge protection system after installation. This may have been an obvious place to install the equipment, but it changes the system’s design and compromises its performance.

-

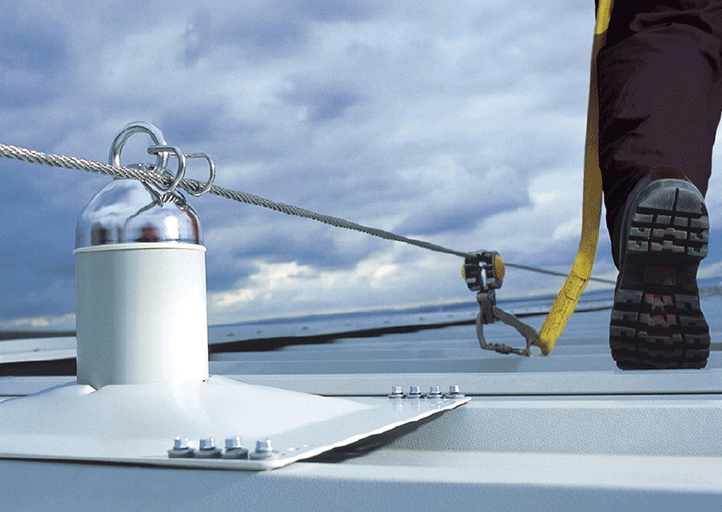

Fall arrest and fall restraint lifelines

Horizontal safety lines comprise 3 components; an anchor point, body harness, and connector such as a lanyard. Each of these must be in good working order to ensure continued safety. If just one part of the system is damaged, the entire system will be compromised, putting the person using it in danger.

For example, brackets can work loose over time or even be installed incorrectly. The system’s shock absorber could have been deployed, or the cable/wire is damaged or kinked.

-

PPE (personal protective equipment)

You need to establish a thorough inspection regime for all PPE such as harnesses and lanyards.

As well as pre-use tactile and visual inspections, detailed inspections by a competent person must be undertaken every 12 months. The HSE and most manufacturers recommend that inspections are carried out every 6 months. When PPE is used frequently, is exposed to sharp edges, paints, chemicals, etc, inspections should be every 3 months.

Common problems include abrasions or cuts to stitching on a lanyard, UV degradation and deformed karabiners, distorted D-Rings on a harness, or there may be missing, illegible, or out-of-date labels.

If the PPE fails any checks or inspections, remove it from use immediately, tag it as damaged, or dispose of it.

Eyebolts and Abseil Anchors

As these tend to be used for external façade cleaning and maintenance access, they must be safe to use every time. Testing and inspection of eyebolts should be every 12 months and abseil points every 6 months. These are in accordance with UK regulations and standards such as LOLER (Lifting Operations and Lifting Equipment Regulations) and BS 7883:2019.

Inspections will identify any structural damage or cracks to the surrounding area and signs of corrosion. They will also check the correct eyebolt marking.

Who can carry out the inspection and testing of your systems?

Everyone using your systems must be trained on the correct use and how to inspect the equipment before use.

When it comes to periodic, detailed inspections and testing, it’s essential you ensure that whoever is conducting the inspection is qualified. They must be knowledgeable about the specific type of fall protection equipment you’re using. They must also be familiar with relevant regulations and standards in your industry.

Fall protection equipment is subject to specific inspection requirements. These include visual inspections, load tests, reviewing the System Technical File, and wind speed calculations. A competent person will be able to assess the equipment and perform inspections thoroughly and accurately. They can also ensure that any necessary repairs or maintenance are completed promptly.

Preventing serious injuries or fatalities

Regular inspection of fall protection equipment is critical for maintaining a safe working environment and reducing the risks of falls and injuries.

If you have any questions or want to discuss the inspection and recertification of your systems and equipment, we’re here to help.