A customer recently asked one of our work at height engineers why they needed to protect the rooflights on their roof.

When you work in an industry, it’s easy to forget that what is obvious to you isn’t so clear to others. So we’ve compiled a list of some of the most frequent questions our customers have asked us about work at height and fall protection.

And if you want to know the answer to the customer’s rooflight question, our Fragile rooflights and skylight safety blog explains all.

What is height work at height?

Since the introduction of the Work at Height Regulations in 2005, work at height is defined as anywhere a person could fall and be injured. This could even be at or below ground level. In other words, work at height is any place where a person could fall a distance that can cause injury.

Examples of working at height include tasks such as roof repairs, window cleaning, painting, M&E servicing and maintenance work.

Who is responsible for work at height safety?

Are you an employer or responsible for the safety of people at your premises, for example, a contractor, building owner or FM? You must comply with the Work at Height Regulations 2005 if you are.

These require you to ensure that all work at height is properly assessed, planned and organised.

How do I make sure someone is competent to work at height?

Always check that the person on your roof has been properly trained to work at height.

This means that they have the appropriate skills, knowledge and experience. If they’re using equipment, ask to see proof that they’re trained in the correct use of the systems. Also, ask for evidence of training and certification from industry trade associations and bodies.

What is fall protection?

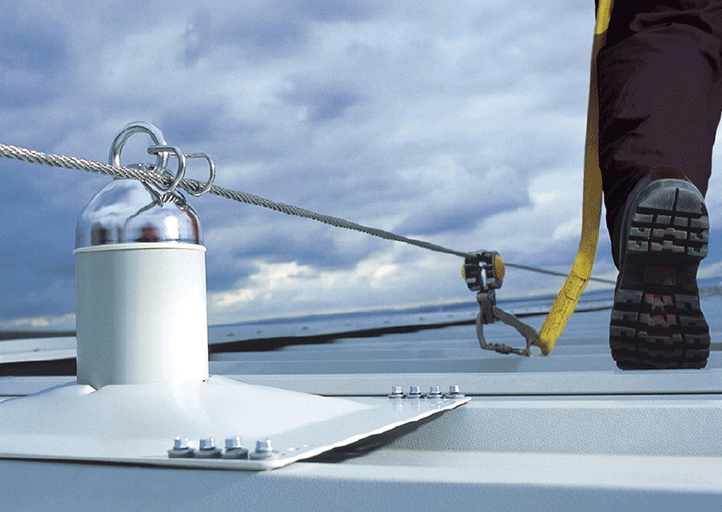

Fall protection refers to a set of measures and equipment designed to prevent or minimise the risk of workers falling from a height. These tend to fall into two categories, collective protection such as guardrails or personal fall protection which includes lifelines and anchorage systems.

Falls from height are a leading cause of workplace injuries and fatalities, and proper fall protection measures help prevent these accidents.

What is the hierarchy of control for work at height?

The hierarchy of control for working at height is a systematic approach (avoid, prevent & minimise) to risk management.

It includes steps such as avoiding work at height, using collective protection, using personal fall protection and training.

What is the difference between collective and personal fall protection?

Collective protection is equipment designed to protect more than one person. These systems don’t depend upon any specialist training or PPE for workers to be protected. Examples of collective protection include rooftop guardrails, access platforms and rooflight covers. Always select collective protection over personal fall protection systems.

Personal fall protection is equipment that relies on user participation. Systems typically require the worker to wear a harness and clip onto the systems with a lanyard. These can be mobile man anchors, fall restraint and fall arrest lifelines. Personal fall protection systems must only be used by people trained to use them.

What is the difference between fall restraint and fall arrest?

Fall restraint solutions prevent someone from reaching a potential fall hazard. This can be done by using a fixed-length lanyard.

A fall arrest system doesn’t stop someone from falling, but it reduces the distance the person falls and arrests them before they hit the surface.

As both solutions need a person to wear a safety harness and to connect to a fall protection system, specialist training is needed.

What fall protection can be used instead of guardrails or lifelines?

Mobile man anchors are ideal when other fall protection systems are not suitable or available.

These systems offer temporary protection for short-term and infrequent work such as roof maintenance.

How often do I need to have my fall protection equipment inspected?

Health and safety legislation such as the Work at Height Regulations require inspection at least annually by a competent person. But, the frequency can change depending on the type of system, how often it’s used, the environment, and the manufacturer’s instructions.

Why do I need to have my edge protection system inspected?

Although rooftop guardrails don’t have any moving components, they should still be inspected by a competent person. Inspections will check that the system has not been altered in any way, there are no missing parts, and it is still performing as it was designed to.

In 2021, BS 13700 introduced guidance on inspecting and recertifying permanent freestanding edge protection systems. This includes wind calculations that are retrospectively applied to confirm the system’s original wind design.

How often should our safety harnesses be inspected?

Safety harnesses should be inspected before each use for any signs of wear and tear or damage. The HSE recommends having your safety harnesses inspected by a competent person every 6 months. But you should also check a harness before each use and conduct more detailed and interim inspections at suitable intervals.

Always follow the manufacturer’s advice on using and maintaining your harnesses.

Do you have a work at height or fall protection question?

When it comes to the critical topic of fall protection and safe work at height, there’s no such thing as a stupid question. Nothing is obvious when you don’t work in the industry.

Everyone has the right to go home safely at the end of every day. If you have any questions about work at height risks or want to discuss your roof safety requirements, contact our experienced team. We’re here to help you work safely.